The purpose of the article is:

(a) To protect the public potable water supply served by the Newton water department from the possibility of contamination or pollution by isolating, within its customers’ internal distribution system, such contaminants or pollutants which could backflow or back-siphon into the public water system;

(b) To promote the elimination or control of existing cross-connections, actual or potential, between its customers’ in-plant potable water system, and non-potable systems; and

(c) To provide for the maintenance of a continuing program of cross-connection control which will effectively prevent the contamination or pollution of all potable water systems by cross-connection. Authority is provided by the Federal Safe Drinking Water Act of 1974, and the Kansas Administrative Regulation 28-15-18. The city water department, as the water purveyor, has the primary responsibility for preventing cross-connections with the public potable water system. The director of water and sewer shall be responsible for the protection of the public potable water distribution system from contamination or pollution due to the backflow back-siphonage of contaminants or pollutants through the water service connection. If, in the judgment of the director, an approved backflow device is required at the city’s water service connection to any customer’s premises, the director, or the delegated agent of the director, shall give notice in writing to the customer to install an approved backflow prevention device at each service connection to the customer’s premises. The customer shall, within 90 days, install such approved device, or devices, at the customer’s own expense, and failure or refusal or inability on the part of the customer to install the device or devices within 90 days, shall constitute a ground for discontinuing water service to the premises until such device or devices have been properly installed.

(Ord. 4046-92, Sec. 1)

In addition to those terms defined in the Uniform Plumbing Code ad adopted for the purpose of this article, the following terms shall hereby be defined to mean:

(a) “Air Gap” is a physical separation between a supply and receptor, of at least twice the supply outlet diameter, but never less than one inch.

(b) “Backflow” is the unwanted reverse flow of water, other liquids, gases, mixtures, or other substances into the distributing pipes of a potable water supply from any source or sources. For specific conditions of backflow, see backsiphonage and back-pressure.

(c) “Backflow Preventer, Reduced Pressure Principle Type” is an assembly of two internally loaded, specifically designed, and independently operated check values including an intermediate relief valve specially designed to maintain a zone of reduced pressure between these check valves, with an automatically opened spillage port to the atmosphere. This assembly is also incomplete without tightly closing, resilient seating shut-off valves immediately upstream and downstream of the device (i.e., ball valve shut-offs or resilient wedge gate valves).

(d) “Back-Pressure” is pressure in a plumbing system higher than the supply pressure which causes a reversal of flow. (Examples: pumps or thermal expansion from boilers).

(e) “Back-Siphonage” is a backflow resulting from negative or sub-atmospheric pressures in the distributing pipes of a potable water supply.

(f) “Barometric Loop” is a loop of pipe rising at least 35 feet, at its top-most point, above the highest fixture it supplies.

(g) “Board” is the Newton Plumbing Advisory Board.

(h) “Contaminant” is any substance that, upon entering potable water supply, would render it a danger to life and health, as determined by the health officer.

(i) “Cross Connection” is any physical connection or arrangement between two otherwise separate piping systems, one of which contains potable water, and the other of which contains water of unknown or questionable safety, or stream, gases or chemicals, where there may be flow from one system to the other. (Note - No physical cross-connection shall be permitted between public and private water distribution systems without prior approval of the director of water and sewer, and protection by an approved backflow prevention device).

(j) “Director” is the director of water and sewer for the city or his or her designated representative.

(k) “Double Check Valve Assembly” is a device consisting of two independently acting, internally loaded soft seated check valves with resilient seated, positive shut-off valves (bait valve or resilient wedge gate valves) on both upstream and downstream ends, and properly located test ports.

(l) “Free Water Surface” is a water surface that is at atmospheric pressure.

(m) “Plumbing” is the practice, materials and fixtures used in the installation, maintenance, extension and alteration of all piping fixtures, appliances and appurtenances in connection with any of the following: Sanitary drainage, venting system, storm drainage facilities, and the on-site water supply systems, within or beyond the supply point to any building, structure or conveyance; also, the practice and materials used in the installation, maintenance, extension or alteration of storm water, liquid waste or sewage, and water supply systems of any premises to their connection with any point of public disposal or other acceptable terminal.

(n) “Pollutant” is any foreign substance (organic, inorganic, radiological or biological) in water that tends to degrade its quality, but does not constitute a health hazard, as determined by the health office.

(o) “Pressure Vacuum Breaker” is a device consisting of both upstream and downstream resilient seated shut-off valves, and at least one tight seating check valve with a relief zone to atmosphere. The valve member opening to atmosphere shall be spring loaded to open under continuous pressure.

(p) “Type R” means general residential dwelling unit classification or district.

(q) “Vacuum” is any absolute pressure less than that exerted by the atmosphere.

(r) “Vacuum Breaker” is a device that permits air into a water supply distribution line to prevent back-siphonage.

(Ord. 4046-92, Sec. 1)

The potable water supply system of the city and the potable water system of private users shall be designed, installed and maintained to best prevent contamination or pollution by non-potable liquids, solids or gases from being introduced into the potable water supply through cross-connections or any other piping connections to the system. Any water being provided by the city water department will fall under the rules and regulations of the cross-connection program. All public or private users being supplied city water directly or indirectly shall conform to standards set by the city.

(Ord. 4046-92, Sec. 1)

Connections to the potable water supply system for the following is prohibited unless protected against backflow:

(a) Bidets.

(b) Operating, dissection, embalming and mortuary tables or similar equipment. In such installation the hose connected to the public water supply shall terminate at least 12 inches away from every point of the table or attachments.

(c) Pumps for nonpotable water, chemicals or other substances. Priming connections shall be made through an air gap or an approved reduced pressure principle assembly.

(d) Building drainage, sewer or vent systems.

(e) Commercial buildings or industrial plants using a contamination or polluting substance.

(f) Any other fixture of similar hazard.

(Ord. 4046-92, Sec. 1)

Except when potable water provided for a refrigerator condenser or cooling jacket is entirely outside the piping or tank containing a toxic refrigerant, the inlet connection shall be provided with an approved backflow preventer. Heat exchanges used to heat water for portable purposes shall be of the double wall type.

(Ord. 4046-92, Sec. 1)

Before any device for the prevention of backflow or back-siphonage is installed, it first shall have been certified by a recognized testing laboratory acceptable to the board. Devices installed in a building potable water resupply distribution system for protection against backflow shall be maintained in good working condition by the person responsible for the maintenance of the system.

(Ord. 4046-92, Sec. 1)

Devices for the prevention of backflow shall be installed as follows:

(a) Atmospheric Vacuum Breakers. Atmospheric vacuum breakers shall be installed with the critical level at least six inches above the flood level rim of the fixture they serve and on the discharge side of the last control valve to the fixture. No shutoff valve or faucet shall be installed beyond an atmospheric vacuum breaker.

(b) Pressure Vacuum Breakers. Pressure vacuum breakers shall be installed with the critical level at least 12 inches above the flood level rim but may have control valves downstream of the vacuum breaker.

(c) Reduced Pressure Principle Backflow Preventer. A reduced pressure principle type backflow preventer may be installed subject to full static pressure.

(d) Devices of All Types. Backflow and back-siphonage preventing devices shall be accessible located, preferably in the same room with the fixture they serve. Installation in the utility or service spaces, provided they are readily accessible, is also permitted. No installation shall be made in pits or any other location not properly drained, unless approved by the director.

(e) Installers. The installation, repair or replacement of a reduced pressure principle assembly, double check valve assembly, or pressure vacuum breaker shall be by a certified technician or licensed plumber. A certified technician shall then test the device and register a test report with the director.

(Ord. 4046-92, Sec. 1)

(a) Installation. Approved devices to protect against backflow or back-siphonage shall be installed at all fixtures and equipment where backflow or back-siphonage may occur and where a minimum air gap cannot be provided between the water outlet to the fixture or equipment and its flood-level rim.

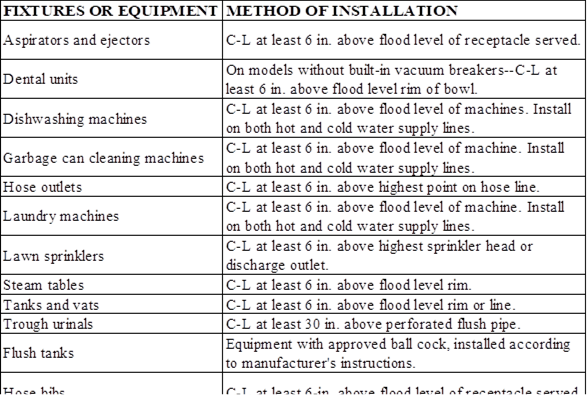

(b) Connections not Subject to Backpressure. Where a water connection is not subject to backpressure, an atmospheric vacuum breaker shall be installed on the discharge side of the last valve on the line serving the fixture or equipment. A list of some conditions requiring protective devices of this kind is given in Table 1 Cross-Connections Where Protective Devices Are Required and Critical Legal (C-L) Setting For Atmospheric Vacuum Breakers.

TABLE 1

Cross Connections where protective devices are required and critical level (C-L) setting for atmospheric vacuum breakers.

Critical level (C-L) is defined as the level to which the vacuum breaker may be submerged before backflow will occur. Where C-L is not shown on the preventer, the bottom of the device shall be taken as the C-L.

(c) Connections Subject to Backflow. Where a potable water connection is made to a line, fixture, tank, vat, pump or other equipment with a hazard of backpressure or back-siphonage, and an air gap cannot be installed, the health officer may require the use of an approved reduced pressure principle backflow preventer assembly or double check valve assembly. A partial list of such connections is shown in Table 2.

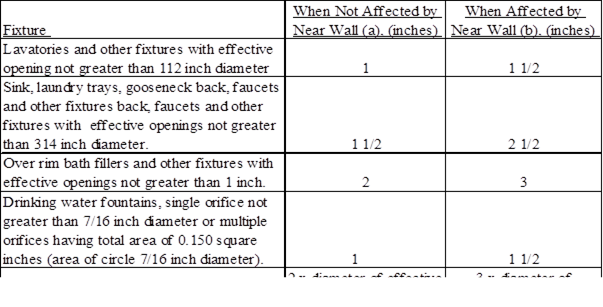

(d) Air gap Requirements. Air gap requirements are contained in Table 3.

Note a. Side walls, ribs or similar obstructions do not affect air gaps when spaced from inside edge of spout opening a distance greater than three times the diameter of the effective opening for a single wall, or a distance greater than four times the diameter of the effective opening for two intersecting walls.

Note b. Vertical walls, ribs or similar obstructions extending from the water surface to or above the horizontal plane of the spout opening require a greater air gap when spaced closer to the nearest inside edge of spout opening than specified in Note a above. In the case of three or more such vertical walls or ribs, the air gap shall be measured from the top of the wall.

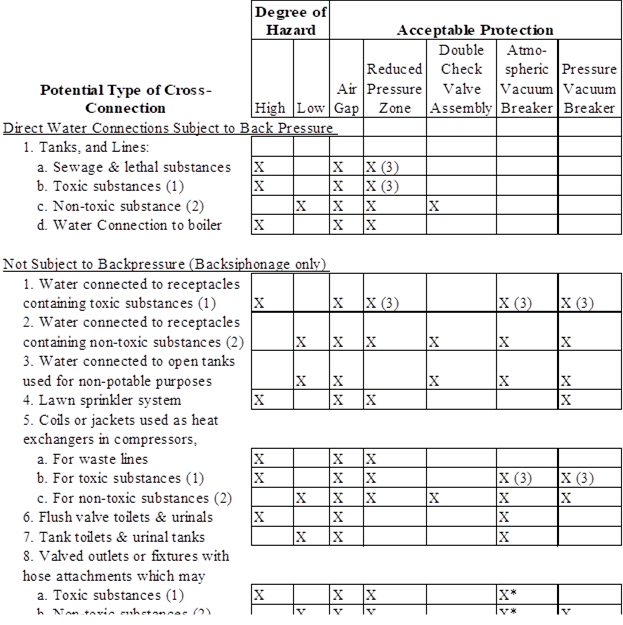

(e) Backflow Prevention Devices which are acceptable for the prevention of cross-connection hazards are contained in Table 4.

*Non-removable Type

Footnotes to Table 4

(1) Toxic Substance: Materials containing contaminants.

(2) Non-toxic Substance: Materials containing pollutants.

(3) Subject to prior approval.

(Ord. 4046-92, Sec. 1)

Water connections where an actual or potential backsiphonage hazard exists may, in lieu of devices specified in section 22-307, be provided with a barometric loop. Barometric loops shall precede the point of connection. There shall be no source of backpressure on a barometric loop.

(Ord. 4046-92, Sec. 1)

The director may authorize installation of approved, double check valve assemblies with test cocks as protective devices against backflow in connections between a potable water system and other fluid systems which present no significant health hazard in the judgment of the director.

(Ord. 4046-92, Sec. 1)

No other devices may be used for the prevention of backflow or back-siphonage unless approved by the board, as being in their judgment equally effective. No device shall be used which requires any special tools for installation or maintenance.

(Ord. 4046-92, Sec. 1)

It shall be the responsibility of building and premise owners to maintain all backflow preventers and vacuum breakers within the building or on the premises in good working order, and to make no piping or other arrangements for the purpose of bypassing or removing backflow devices.

(Ord. 4046-92, Sec. 1)

The owner/tenant of a property shall be responsible to submit certified test reports to the director as required by the testing schedule from the device. An initial registration fee shall be charged to the owner according to a fee schedule which has been established by the director. Testing schedules shall be established for all backflow preventers and the interval between such testing and overhaul of each device shall be established in accordance with the age and condition of the device. Testing intervals should not exceed one year, and overhaul intervals should not exceed five years. The testing procedures shall be in accordance with the manufacturer’s instructions and nationally accepted practices. Testing and repair of the backflow devices will be done by certified testers, trained as tester/repair technicians that meet the requirements set up by the director. Maintenance works, trained as tester/repair technicians can service backflow preventers in their place of employment. The city building official shall verify proper installation of backflow prevention devices in new construction and refer them to the director of registration.

(Ord. 4046-92, Sec. 1)

All tester/repair technicians shall have completed a course approved by the director and be certified by the director. Tester/repair technicians shall be tested and recertified every three years. Recertification tests shall be to the latest accepted practice methods. Those persons certified as tester/repairmen at the time of passage of Ordinance No. 4046-92 shall continue to be certified for a period of three years. All tester/repair technician certificates shall be renewed annually upon payment of a fee established by the director. All such certificates shall expire on the 31st of December of each year, and no reduction shall be made for a part of the year being elapsed.

(Ord. 4046-92, Sec. 1)

All testing devices shall be approved by the director and shall be compared for accuracy at least every three years.

(Ord. 4046-92, Sec. 1)

The director of the water department may refuse to deliver water through pipes and mains to any premises where a condition exists which might lead to the contamination of the public water supply system, and may continue to refuse the delivery of water to the premises until the condition is remodeled.

(Ord. 4046-92, Sec. 1)

If the director determines that the condition of the plumbing constitutes an extreme hazard to the potable water supply, the director shall notify the owner of the premises as to the hazardous condition. Immediate action, within 24 hours, to correct the condition shall be taken or water service will be shut off until that condition no longer exists. In the event of any addition, repair, replacement or alterations are made to such plumbing, other than routine maintenance, the entire system shall be brought into compliance with provisions of this article.

(Ord. 4046-92, Sec. 1)

All automatic fire suppression systems of 30 hears or more, or having a fire department connection, other than dry systems, shall be protected from backflow with an approved double check valve assembly. Backflow preventers shall be no smaller than the line size of the underground lead. Any fire suppression system into which chemicals of any type (corrosion, anti-freeze, etc.) can be added shall be protected at the service connection with an approved reduced pressure principle assembly. In lieu of such protection, an anti-freeze loop may be individually protected with an approved reduced pressure principle assembly, in addition to proper service line protection.

(Ord. 4046-92, Sec. 1)

All existing fire suppression systems shall be retro-fitted within five years of the passage of Ordinance No. 4046-92 to meet the requirements provided herein.

(Ord. 4046-92, Sec. 1)

All temporary water services for projects under construction shall be protected from backflow. Services for two or less story buildings may be protected with an approved double check valve. Buildings of three or more stories shall have an approved reduced pressure principle assembly backflow preventer installed on the construction water service. Type “R” occupancies shall be exempt from this requirement.

(Ord. 4046-92, Sec. 1)

Any corporation, railway, common carrier, company or individual violating any of the provisions of this article is guilty of a misdemeanor and, upon conviction, shall be punished by a fine not to exceed $500 or by imprisonment of not more than six months, or by both such fine and imprisonment. Each day any violation hereof is found to exist or continues to exist shall be a separate offense and punishable as such hereunder.

(Ord. 4046-92, Sec. 1)